INCONEL SHEATHED THERMOCOUPLE PROBES

Inconel is a set of nickel and chromium alloys with properties of high resistance to high temperatures, oxidation and corrosion.

Thermocouples remain one of the most versatile systems used in temperature measurement processes. The characteristic operating range of these solutions is very inclusive and extensive to several industries. The sheath applied on these equipments has a strong influence on their durability, mechanical stability and toughness. Among the various materials available today, we look at a set of metal alloys with distinctive characteristics, namely the melting points and chemical resistance: Inconel coating alloys.

Inconel is a set of nickel and chromium alloys with properties of high resistance to high temperatures, oxidation and corrosion. Regardless of being a metal, it has no magnetic properties and has excellent mechanical properties. Inconel heating forms a thick and stable layer of oxide, which strengthens the surface of the material. This set of alloys was designed to operate at temperatures ranging from cryogenic level (< 150ºC) to continuous temperatures in the 1100ºC range typically applied to Inconel 600.

The application of Inconel coated thermocouples in environments with temperatures below 600ºC has tended to reduce their degree of ductility (degree of deformation) as well as their physical resistance. Sulphurous environments are typically detrimental to the resistive capacities of these alloys.

The mechanical properties of this alloy offer great resistance when subjected to different pressures. The pressure to which thermocouple is exposed is one of the factors that interferes on its durability. In cold work, the pressure exerted exponentially reduces the thermocouple’s service life.

The correct production of Inconel sheathed probes has a high degree of dependence on the knowledge of the environment in which the equipment will be installed. Gathering as much information about the variables arranged in this environment is a critical step in producing the right probe type. This preliminary check makes it possible to prevent certain flaws in the temperature measurement process.

The diameter of Inconel coated probes is one of the aspects where the standard for its choice will impact some variables directly related to the operation of thermocouples: duration, exposure temperatures and temperature drifts. In the XXI IMEKO World Congress, a study was presented demonstrating the interference of Inconel 600 thermocouple diameters on temperature drifts over the time of exposure to high temperatures.

CHEMICAL COMPOSITION

Inconel metal alloys have distinct chemical compositions in each type, with unequal percentages between each element, but constantly maintaining nickel as the main element and chromium as the secondary element.

Table 1 - Chemical composition of different types of Inconel

MINERAL INSULATION

The use of Inconel sheathed thermocouples is mostly directed to applications where procedures / phenomena subject to high temperature ranges occur. The distinction of these thermocouples from conventional ones also lies in their mineral insulation. The mineral insulation does not set itself on fire making it ideal for high temperature.

Even exposed to temperatures above 1000°C, mineral insulation retains all its electrical insulation properties, which distinguishes it in the chapter on resilience to electromagnetic interference.

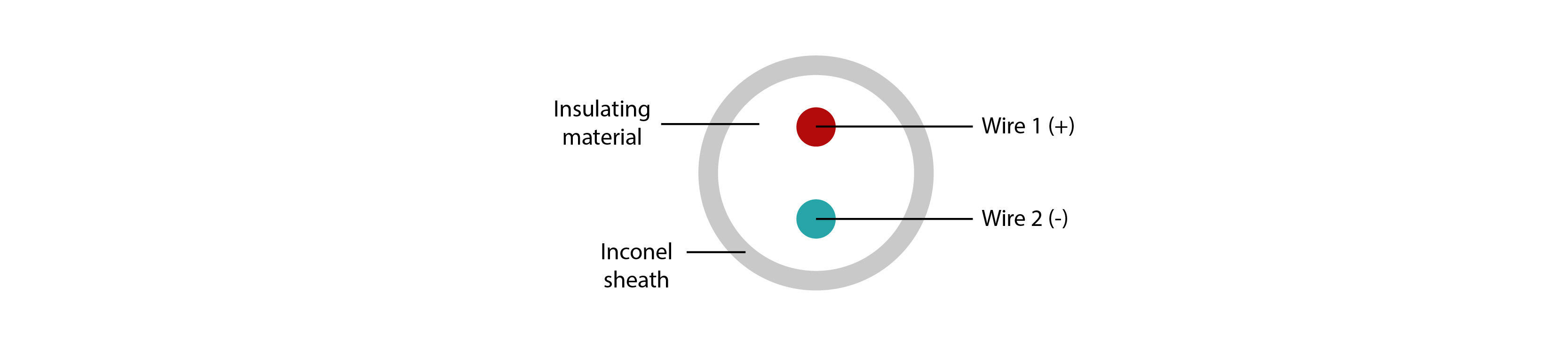

Figure 1 - Thermocouple top view

The probes flexibility is also dependent on the materials used in the insulation between the thermocouple and the sheath that covers it. The characteristics of the atmosphere in which the thermocouple will be installed play an influential role in the choice of insulating material. Their different compositions and operating temperatures affect the strength and durability of the solution and should offer the physical and chemical stability required to operate in extreme environments.

Elements used in mineral insulation have a susceptibility to temperature and relative humidity conditions that restrain their application and perfect thermocouple insulation. These materials exhibit rapid humidity absorption and therefore require strict environmental control in the production process of Inconel sheathed probes. Humidity is a major cause of mineral insulation deterioration and may turn the thermocouple unusable by reducing insulation resistance. Thermocouple accuracy is thus directly conditioned by the probe's mineral filling process.

More often, we find insulation materials with the following attributes:

Table 2 - Chemical formula of the most common mineral insulation

INCONEL PROBES AND THERMOCOUPLE TRANSMITTERS

Tekon Electronics, as an organization focused on the production of temperature transmitters is complemented by its business model, a department with increased capacity for the development of level and temperature probes with the guarantee of a unique service complementary to customer needs.

The production of Inconel sheathed temperature probes is a demanding process that must take place in controlled environments. At Tekon Electronics, the facilities are well-prepared to provide right storage and production conditions for Inconel sheathed thermocouples. Cold frame equipment is properly monitored in real time to provide a thorough level of quality, where temperature and humidity are extremely influential variables in the production of this type of probes, as previously mentioned. The welding process with Inconel is performed by dedicated equipment that values and certifies the quality required for this procedure.

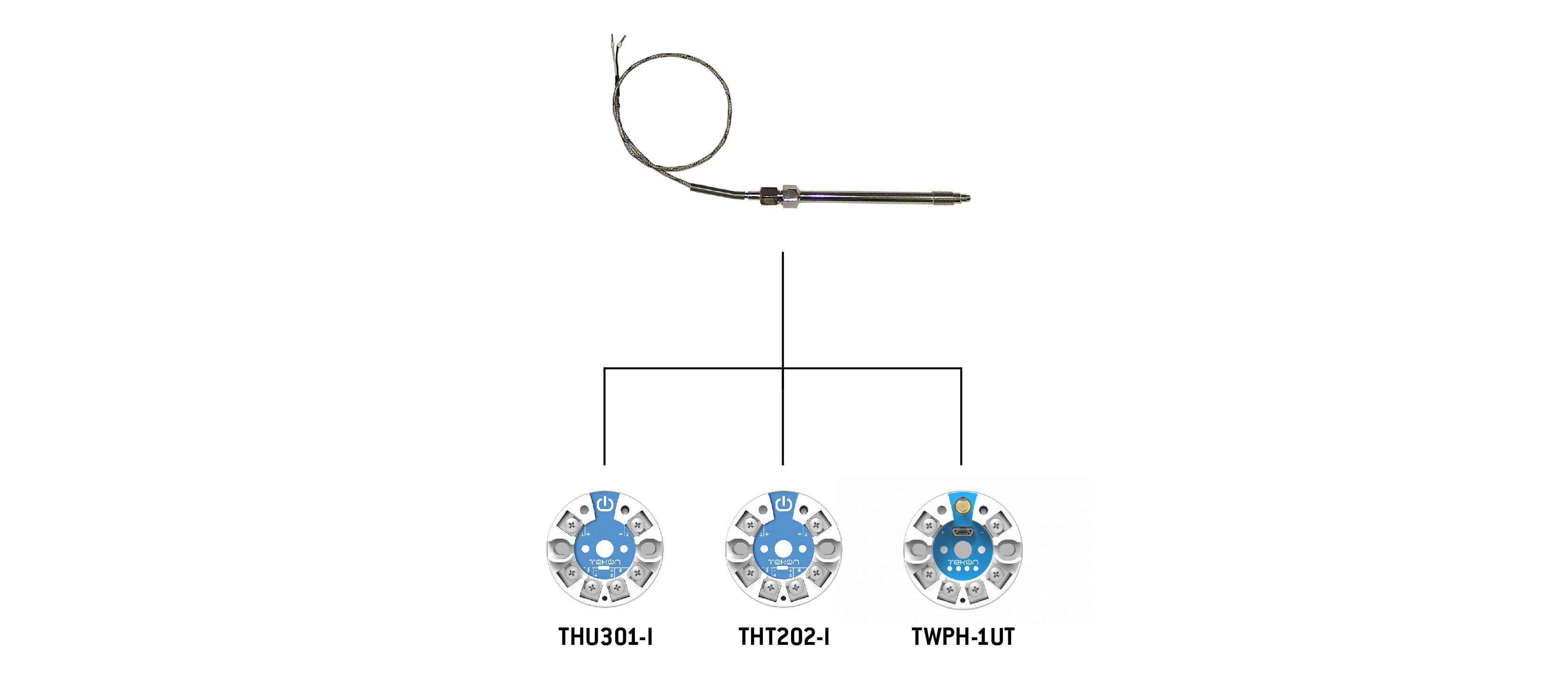

Continued use of thermocouples in temperature measurement procedures is complemented at Tekon Electronics by the development of transmitters capable of supporting connection with these sensors (thermocouples). The communication methods of temperature transmitters have been developed in wired and wireless segments in order to leave their application open to different environments. The output signal of head transmitters is characterized by its mA format, in a range of 4 to 20, via Modbus RTU communication protocols for wired models, and via TinymeshTM protocol for wireless models.

Figure 2 - Tekon Electronics inhead transmitters with thermocouple connection

To learn more about Inconel thermocouple probes and thermocouple link transmitters, follow the links placed on the “More Information” tab.