How IoT Monitoring is Changing Cold Chain?

The global cold chain market has been growing sharply due to the consequent demand for products that fit into the most relevant industries to this sector.

The global cold chain market has been growing sharply due to the consequent demand for products that fit into the most relevant industries to this sector - food and beverage, pharmaceutical and medical devices.

In a general view, the cold chain is a set of infrastructures that respond to the processes of distribution and storage of food, medicines, chemicals and other materials sensitive to temperature fluctuations. The term “chain” comes from the union between the multitude of players and their different competencies regard to production, storage and transport, distribution agents and infrastructures responsible for exposing the product in various formats to the end customer.

Real-time monitoring of this sector's own processes acts as a security measure for two of the key concerns that agents seek to minimize impact on their business model - energy costs and waste losses.

Both issues are current issues with increased civil liability and as such their transposition to inclusive cold chain markets is spontaneous. The energy resources directed to the maintenance of the cold chain have a significant expression in the final price of the product or service. The high consumption required to keep equipment up and running most of the time, working around the clock, 7 days a week means rethinking energy savings from its source of supply to the application of equipment and measures that improve energy performance of infrastructures and reduction of operating costs.

Failures in the processes that form the cold chain tend to compromise product integrity. Disabling it as an asset imperatively results in damage to organizations. As the food industry is one of the most served by the cold chain and where the traded goods are perishable by nature, all conditions must be ensured so that the fullness of their properties is protected throughout the process.

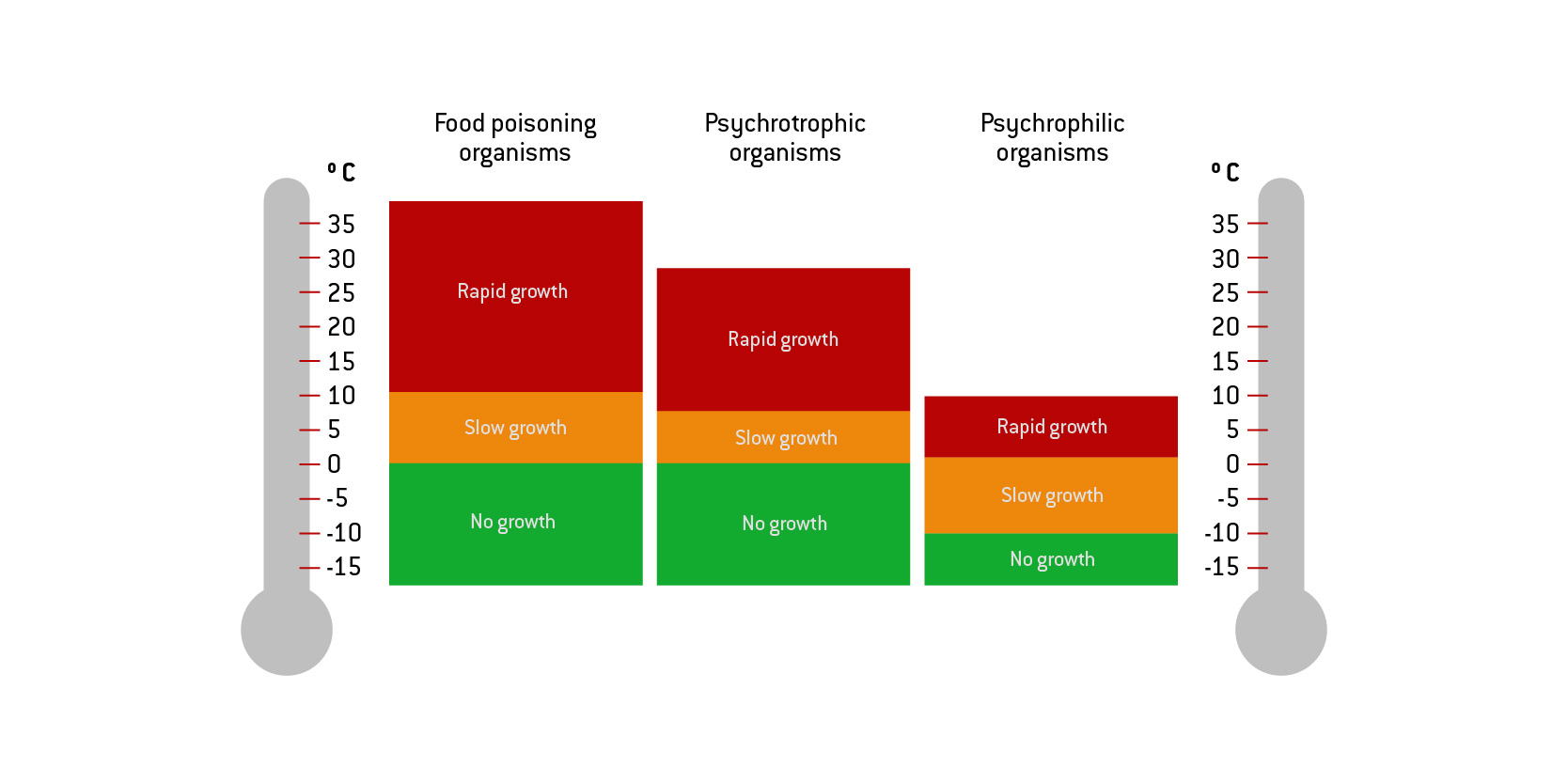

Fonte: WFLO Commodity Storage Manual

Figure 1 - Temperatures showing growth of organisms in frozen foods

Real-time monitoring acts as an on-site agent for reducing and fighting food waste. According to a study published by the Boston Consulting Group (BCG), worldwide food waste is close to 1.6 billion tons and by 2030 it is expected to reach 2.1 billion tons, which translates into 1.5 trillion of dollars! The cold chain is taking steps behind the scenes to ensure its contribution to reduce these values. IoT monitoring has been one of the assets used to minimize the impact of this issue. The confirmation of the impact that the cold chain has on food waste is the holding of debates and summits that analyze the global panorama of the theme.

MOVING FROM REACTION TO PREVENTION

Internet of Things (IoT) has strengthened the visibility and control of operations throughout the cold chain. Improving corporate responsibility for the safety of temperature-controlled products has indexed a shift in position - from reacting to safety issues to active prevention.

Real-time monitoring returns the data needed to set up the necessary preventive measures to be performed. The challenges observed are maintaining energy efficiency, balancing temperatures and ensuring continuous uninterrupted operation.

To avoid failures, cold chain operators, namely storage providers, have been implementing monitoring solutions under the IoT technology concept, usually with the incorporation of intelligent sensors.

Tekon Electronics is a distinct partner to cold chain organizations by providing solutions designed to streamline real-time IoT monitoring systems. The verticality of the solutions ranges from sensor development to sending, permanent storage, presentation, analysis and alarmistic on the collected data. The DUOS family products has the toughness and operational characteristics required for the extremely cold environments that are part of the cold chain. Its IP67 protection index ensures correct operation even in contact with water. The operating range of DUOS family products enables them to maintain plant performance in harsh environments up to -40 ° C.

Take action based on preventive measures, it provides a support foundation with specific data on equipment that transmits to the user the current state of operations. This report is no more than the translation of the data recorded by the sensors. Tekon IoT Platform was developed as a tool that completes IoT monitoring by providing a graphical interface that presents data from a permanent logging database. This API has a high level of versatility by allowing interconnection with third party devices, thus adding value to previously deployed installations.

Prevention starts from the implementation of measures that ensure certain key positions for the business. The correct functioning of cold equipment is one of these provisions. Their constant monitoring lets you know if metrological intervals are being met. As an aid to this task, the configurable alarm system on the Tekon IoT Platform makes it possible to set operating limits for the environments and issue alerts and notifications to the user via email or sms when these limits are not respected regardless of the influencing factor.

FINAL CONCLUSIONS

Efficiency and optimization are the milestones that IoT monitoring aims to reinforce in the cold chain. Minimizing the impact of human error focuses stakeholder's attention on the measures needed to make this process more profitable for their business. With these advances in the cold chain market, information is transformed into energy. The benefit of including these solutions goes beyond the expected financial return and makes the end customer the great beneficiary.

Learn more about Tekon IoT Platform and Tekon Electronics wireless monitoring solutions. Contact the sales department for the follow-up you need.